A Profiled Wire for Every Industry

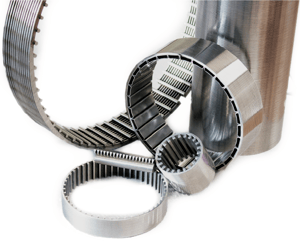

Profiled wire is a versatile product that can be used in a wide range of applications and industries. Profiled wire is often found in screens used for mining because the strong physical structure and customization often makes wedge wire screens preferable to mesh ones. In the manufacturing sector, profiled wire serves as a creative alternative round wire used to produce hardware, springs, and other small components. From small components to large finished products, and everything in between, it can be employed virtually anywhere.

Wedge profiled wire is one of the most common forms used in screens for the mining industry. Typically manufactured from stainless steel, these screens are durable enough to withstand intense vibration, crushing forces, and heavy weight. Not only can they be customized to a wide range of sizes for different machinery setups, but they can also be configured to allow different materials to pass. By adjusting the spacing between the different lengths of wedge wire, these screens can process everything from salt and sand, or coal and gravel.

Wedge profiled wire is one of the most common forms used in screens for the mining industry. Typically manufactured from stainless steel, these screens are durable enough to withstand intense vibration, crushing forces, and heavy weight. Not only can they be customized to a wide range of sizes for different machinery setups, but they can also be configured to allow different materials to pass. By adjusting the spacing between the different lengths of wedge wire, these screens can process everything from salt and sand, or coal and gravel.

Profiled wire is also used to produce clips, pins, springs, and other types of hardware. Manufacturers can choose between standard oval, square, flat, or triangular wires, or they can specify hex, star, or other custom forms. Profiled wire is often preferred to traditional round wire because each individual form offers unique physical qualities that impact the performance of finished products. Springs manufactured from flat wire instead of round wire, for example, produce more force for equivalent size and material selection, allowing for smaller sized springs to be used in tight spaces.

To learn even more about the different ways profiled wire is used in nuclear, architectural, medical, and agricultural industries, visit our website. If you are interested in specifying a custom profile of your own, simply contact us today. Our engineers are always available to help you.