CWI Craftsmanship Makes Our Equipment Produce the Finest Wire

Looking through the windows of CWI plants, you can’t see the extent of technology and workmanship embodied by our equipment. Some machines shine, obviously advanced in every way. Others appear well used. But don’t be deceived; they likely click and gleam with high-tech workings inside. Central Wire Industries operations are modern and forward-moving, and our machinery is often remodeled and rebuilt, customized for precision.

We have modernized and upgraded numerous wire production lines as well as ancillary treatment equipment over the years. Employees have been given the OK to use their skill and experience to craft what the shops need. CWI often strips an old piece of equipment to the frames and studs and rebuilds a new machine that more accurately meets our customers’ needs than anything on the market. The process combines the operational and maintenance expertise of our machinists and millwrights with advanced software design, such as Solidworks, as well as modern PLC (programmable logic controller) and HMI (human machine interface) upgrades.

Tear It Down To Build It Up

When refurbishing an older piece of equipment, we tear it down to its basic frame, and then build it back up with new shafts, bearings, pulleys, motors, and control systems to make it much more user friendly as well as faster and more efficient.

Being able to fabricate our own machines means we do more work in-house, without having to contract portions of jobs out. It means we can build the machinery to fit our floor space instead of buying, selling, or building to create room for equipment. In the end, the products produced, be it profile wire or wire rope, are among the highest quality and most precise available.

Storehouse of Knowledge and Skill

CWI comes by the ability to build and customize its equipment because of staff of long-time workers with a storehouse of knowledge and hands-on experience. Employees include engineers, technicians, and metallurgists who work in our in-house QA/QC testing labs to verify the accuracy of size, texture, density, pattern, and strength of products and the machines that make them. Our craftsmen, from Europe to North America, are masters of their art and have used their knowledge of drawing and shaping, of heat and pressure, to expertly construct and upgrade much of the company’s highly specialized equipment.

When our Union plant began processing larger diameter spring wires that have break loads over 60,000 pounds, the facility was not equipped to handle it. They incurred extra cost and lost time because they had to hire outside labs.

It was decided to relocate a much larger tensile testing machine from Lancaster, SC. Unfortunately, the machine wasn’t quite ready for loads of 60,000-plus pounds that needed testing. But the Union technicians determined how to make it work. They upgraded parts and the display and coordinated with a local company to calibrate the machine. The Union facility can now test sample a maximum break load of 200,000 pounds – on a machine that looks retro.

Designed and Built from Scratch

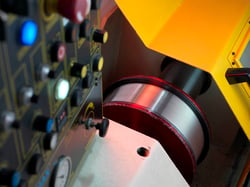

This craftsmanship not only applies to existing equipment but to new equipment requirements as well. When CWI re-introduced Generation4 welding wire to its product line, it designed and manufactured a key piece of TIG wire equipment in-house. The TIG welding wire printer is a highly specialized piece of equipment conceived and built from scratch to ink-print identification on the wire instead of stamping or embossing it.

CWI also makes sure our remodeled and rebuilt equipment meets strict safety requirements. Often stock machines don’t meet strict ergonomic and safety standards either. Our staff of millwrights, machinists, electricians, and welders, not only repair and maintain equipment, they modify, upgrade, and improve it.

In another show of skill and precision, our in-house technicians service and modify their own drawing dies. A .0120 will never reach .0125 diameter on their watch. Because of their ability to contour dies, they can carve a worn die to another diameter, giving it new life. CWI can produce round and flat wire from 1.00” (25.4mm) down to 0.002" (0.0508mm), smaller than a strand of hair, with unmatched precision. As an added talent, at CWI-UK in Rotherham, technicians custom craft the dies for the profile/shape wire. With three locations now manufacturing shaped wire, this is an in house capability un-rivaled in the industry.

Craftsmanship is appreciated in many fields. Manufacturers of specialty spring and mesh are known for their crafting operations; CWI’s wire-drawing and machinery craftsmanship is akin to any of those with attention detail, quality, and precision. CWI is fortunate to have craftsmen—drafting technicians, engineers, metallurgists, welders, machinists, and more—on our in-house teams, workers skilled with seeing needs, visualizing designs, and making things with their hands. With our constant innovation, commitment to quality, and outstanding service, we are proud to be your trusted leader in the wire and cable industry.